Stamp Die Cutters

Put our stamp-die cutters to work for you and watch efficiency and accuracy increase!

These machines are an inexpensive way to increase productivity in your stampmaking operation. The units can be used to cut perfectly straight lines, circles, and custom shapes to conform to your stamp-copy. Every cut is at a square 90-degree angle in relation to the printing characters, eliminating undercut and non-supported letters and figures. Excellent results will be obtained with rubber, photopolymer, and pre-inked stamp-dies.

Operation begins by placing the sheet of stamp-dies on the left side of the aluminum work-table. The sheet is fed past the blade as the operator pulls the cutting lever with his or her right hand. Besides close trimming of stamp-dies, the Stamp Die Cutters also conveniently make "rough cuts" on large sheets of various die-sizes and -configurations, separating them from the full sheet before final trimming.

Blades are made of a special steel alloy, hardened to 41-44 Rockwell C. They are six-point (.083") thick by 1-1/2" in height. Blades stay sharp for long periods under heavy usage. Standard blades cut the stamp-die completely while "perforating" blades leave tiny sections intact so that the customer may rip the die apart like a perforated sheet of paper. The perforating blades are designed for cutting "art stamp" kits mounted on dense-cell cushion. The aluminum cutting-plate mounts on the cutting-table, providing a sturdy cutting surface, and should be replaced with the blade.

All Stamp Die Cutters are covered by a one-year limited warranty.

Pneumatic Model P-4

Pneumatic Model P-4

Model P-4 is truly a revolution in the way stamp-dies are trimmed! Compressed air drives the cutting blade through the stamp-die with the touch of a foot pedal, leaving both of the operator's hands free to position the die. Once the die is turned to the desired trimming location, less than a second is required for the blade to make a cut. The height of the blade is adjustable so that only the backing of the stamp -- not the printing characters -- can get under the blade. This makes it impossible to cut into the print and allows for exceptional speed since the operator can simply slide the die against the blade to make a cut. There is no need to visually align the blade against the die.

One P-4 machine will accommodate either of two cutting blades. Head "A" is designed for unmounted rubber and polymer stamps up to 3/16" thick. Head "B" has the blade mounted higher and provides a longer cutting stroke for cutting rubber mounted on sponge-cushion, rubber mounted on dense-cell foam, and pre-inked slabs up to 1/2" thick. Heads can be changed in about a minute.

The P-4 Pneumatic Stamp Die Cutter includes an air-pressure gauge and air-regulation system. An air compressor generating 90 to 130 psi is required for operation (available as an option or may be obtained locally). Use dense "chipboard" cardboard under the stamp-die as a cushion for the blade and to provide a work surface for sliding the die under the blade. A 60-watt worklight, a 25-foot length of airhose, and a tool kit for adjusting blade position and cutting-blade depth are standard equipment with the P-4. The foot pedal and cutting blade are both steel-guarded for safety. Available for operation on 110v-220v 60Hz North American electrical power, or 220v-240v 50Hz power for export.

Model G-12

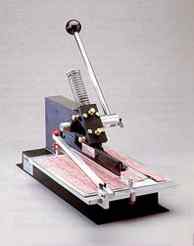

Model G-10 & Model G-12

Models G-10 and G-12 bring the cutting blade down with a guillotine-like action and "slice" the die. The G-10 offers a 10" maximum cut-length, while the G-12 provides a 12" cut. The ram is set at a 55-degree angle in relation to the cutting-table. This is especially beneficial when cutting thick, fragile materials such as pre-inked stamp-dies and sponge-rubber cushion. The optional clamp-bar prevents sliding when making long cuts in rubber or photopolymer dies. The clamp-bar is spring-loaded and adjustable for various die thicknesses up to .225". The clamp-bar can be easily removed from the cutting-table by loosening the clamping screws. The clamp-bar is not recommended for pre-inked dies.

Model S-6

Model S-6

The Model S-6 Stamp Die Cutter brings the cutting-blade down squarely with the cutting-table and "chops" the die rather than slicing it like the guillotine-action cutters. The standard or perforated blades make up to 6" cuts. A variety of optional cutting units make the S-6 our most versatile cutting machine. Perfect circles in 10 different diameters can be cut with the optional round cutting-dies. Rectangular blocks can be cut from the center of stamp-dies for die-plate dater bands. The S-6 is the cutting machine recommended for use with our Custom Contour Cutters (see below).

Custom Contour Cutters (CCCs)

Hit the jackpot in efficiency with a whole new way of trimming stamp-printing dies. Just like pulling the handle on a Las Vegas slot machine, pull the handle of the S-6 Die Cutter and accurately trim your most popular images.

The system allows you to trim rubber, rubber mounted on cushion, rubber mounted on dense-cell cushion, pre-inked and photopolymer stamp-dies. Custom Contour Cutters can be configured for each of your most popular stamp images.

CCCs consist of two elements. A piece of hardened-steel rule (much like a razor blade) is bent to form the shape of your stamp image. The bent-rule is then embedded into a clear acrylic backing-block that you can see through in order to align the bent rule precisely over your stamp design.

Cutting the image is simple and very fast. Position the CCC over one of the stamp designs. It is easy to locate since the cutting blade will nestle over the raised image. Now position to CCC under a "pressure-plate," which attaches to the ram of the S-6 Cutter. When the handle of the S-6 is pulled, the ram and pressure-plate move downward, pushing the CCC through the stamp material and stopping when the CCC touches the hard cutting-surface below. In a matter of minutes you will have a pile of perfectly trimmed stamp-dies!

PRICE: A number of variables go into determining the cost of CCCs, including the overall size of the image and the number of bends that must be made in the steel-rule to conform to the shape of your stamp. We quote the cost of each CCC based upon these criteria and also the number of CCCs that you intend to order. Fax us your stamp designs for a quotation.

Hydraforce Slab Cutter

Hydraforce Slab Cutters

Imagine taking a minute or less to cut an entire 13" x 13" plate of rubber stamp dies, polymer stamp dies, rubber dies mounted on cushion, polymer dies mounted on cushion, or pre-inked stamp dies. Completely eliminate tedious cutting with scissors, knives, or scroll saws. The Hydraulic Slab Cutter and Pneumatic/Hydraulic Slab Cutter (shown) will do the job accurately every time.

Consistent placement of stamp images allows for use of an acrylic and steel cutting unit that is formed to your specifications. Pieces of hardened steel rule (much like razor blades) are aligned or bent to form an outline of the stamps. The steel rule is then embedded in a clear acrylic backing block that allows the user to align the bent rule precisely over the stamp designs. Cutting straight lines, circles, ovals, and irregular shapes are all possible with the system.

Sets of arts stamps that are mounted on thick, dense cell cushion can be cut with perforations between the images. The customer then breaks the set into individual stamps. Perforation cutting units are an option that can be supplied.

The Hydraulic Slab Cutters require manual pumping of the handle to create pressure. The Pneumatic/Hydraulic Slab Cutters are faster and more efficient since pressure is created simply by pressing two activation switches. Pneumatic/Hydraulic Slab Cutters require an air compressor for operation.

Die Cutter Specifications

Hydraforce Slab Cutter Specifications

Request Literature

Equipment Price List

Copyright Jackson Marking Products 2006